Dialogue in Progress

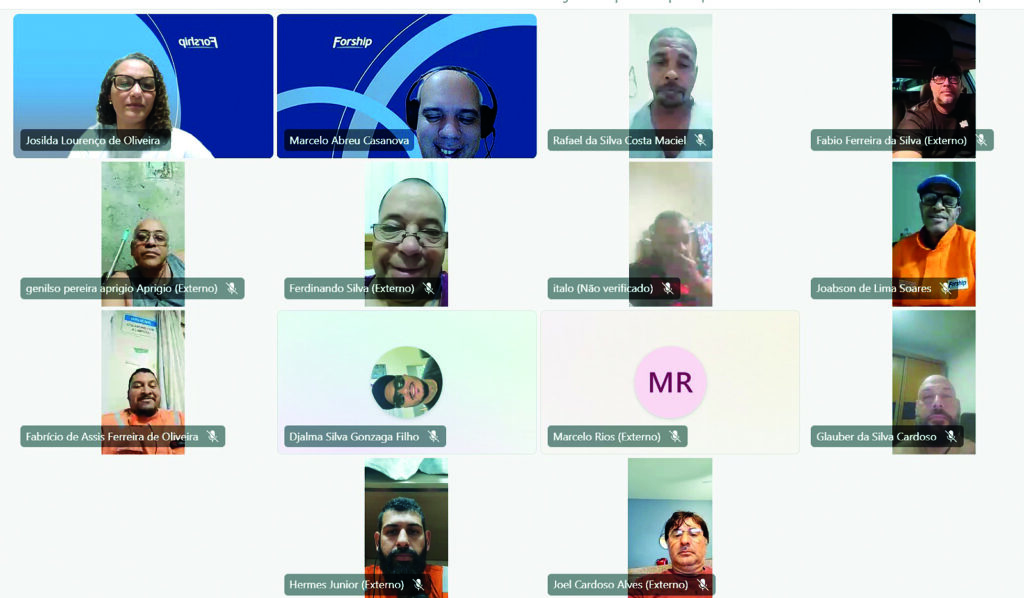

It all started with the “Direct Talk with Supervisors” (PDS) Strengthening communication and alignment in the Petrobras client projects at UN-BS and UN-ES was the goal of initiatives aimed at establishing a permanent dialogue with Forship Group employees. The first of these initiatives was the Direct Talk with Supervisors (PDS). “We identified the need to talk with supervisors about the responsibilities they hold in managing the contract,” explains coordinator Sebastião Filho. “That’s how PDS was born. Questions from the teams on administrative matters motivated us to create PDE (Direct Talk with the Team). The two are complementary,” adds the coordinator of the initiative, which is led by project managers Marcelo Casanova (UN-BS) and Pedro Henrique Alcântara (UN-ES). Established Benefits PDS began in September 2024 with the UN-ES project team, and a month later with the UN-BS team. Through weekly remote meetings, which ensures broad and flexible participation, 44 meetings have been held so far with 19 supervisors from the UN-ES area, and 40 meetings with 28 supervisors from UN-BS projects. The main benefits include: greater integration between supervisors, management, and peers from other platforms; standardization of activities and best practices across contracts; faster information exchange regarding materials, training, and audits; and a reduction in communication gaps between the operational team and supervision. Lessons Learned “The exchange of information between project management and supervisors is encouraging greater integration, a shift in attitude, and an easier understanding and fulfillment of contractual items,” notes Sebastião Filho. “In one of the meetings, a supervisor brought up a problem with no apparent solution. A colleague quickly shared a similar experience and the solution they had implemented. This kind of collaborative exchange illustrates the value of PDS in promoting synergy and agility in problem-solving,” he adds. According to him, there is still potential to further enhance the PDS by expanding the agenda to include success stories and lessons learned; conducting quick post-meeting surveys to gauge satisfaction and identify areas for improvement; and promoting cross-mentorship sessions between senior and junior supervisors. “Through these actions, we will continue to improve the direct communication channel with our supervisors, ensuring efficiency, transparency, and excellence in project management,” he concludes.

Dialogue in Progress Read More »