Commissioning

Commissioning

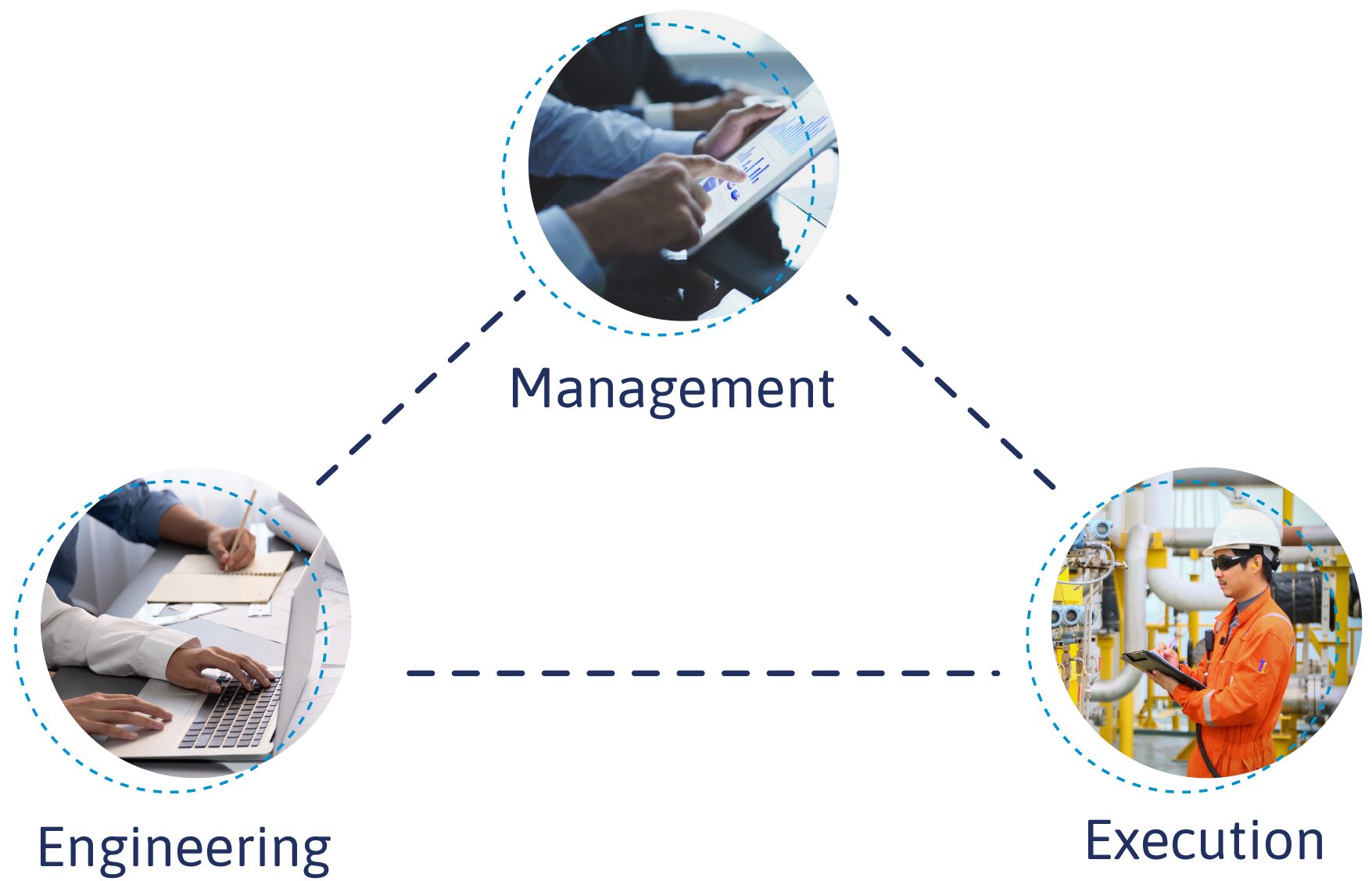

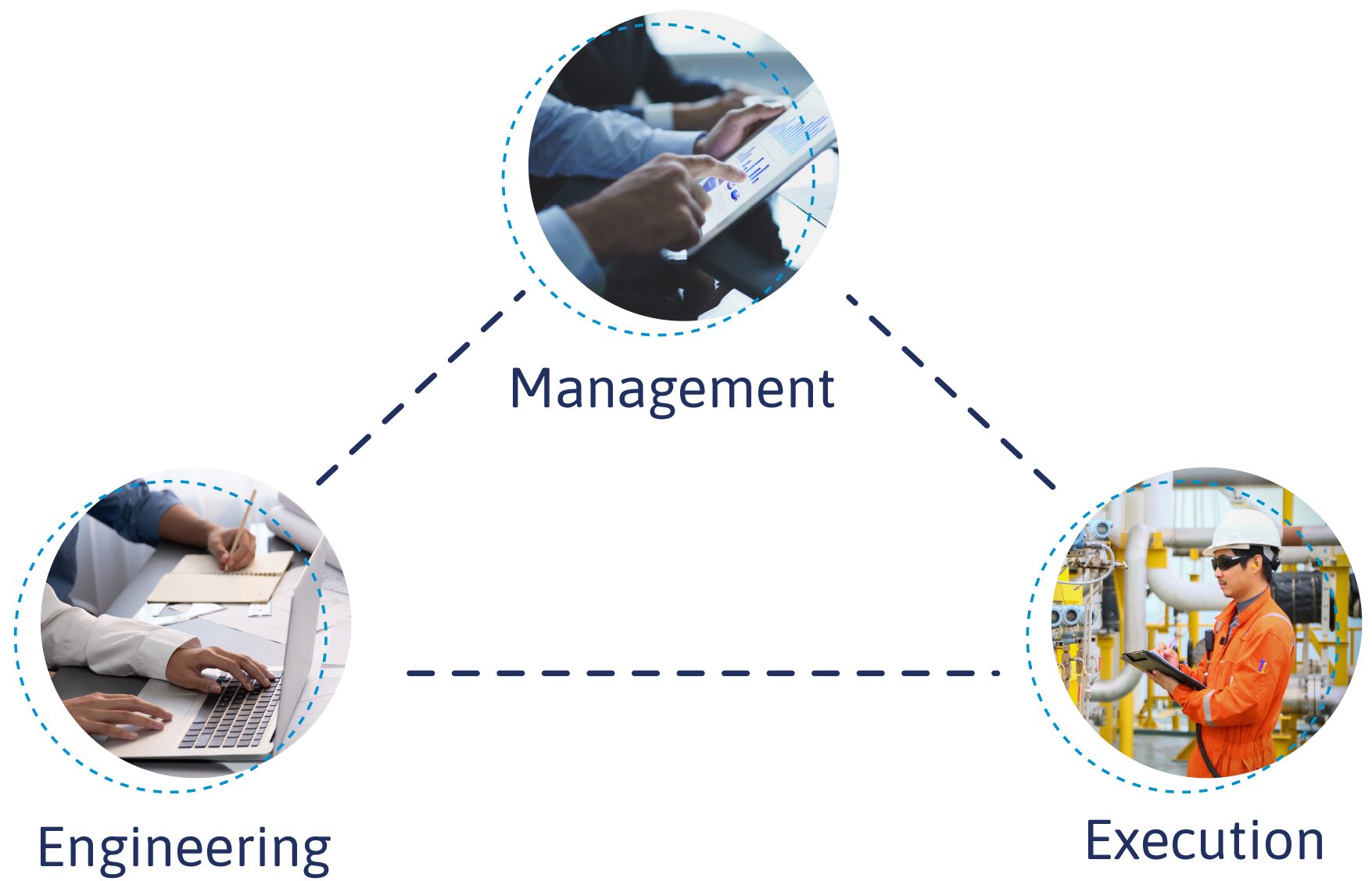

Forship’s success in Commissioning is due to its innovative three-pronged approach:

Forship Methodology

The company’s management technology is supported by a methodology aimed at ensuring operability through four key factors throughout the EPC project, particularly during the crucial process of handover of the unit to the operator.

Forship Methodology

The company’s management technology is supported by a methodology aimed at ensuring operability through four key factors throughout the EPC project, particularly during the crucial process of handover of the unit to the operator.

Excellence in Performance

Excellence in Performance

Commissioning engineering is carried out by the project teams, supported by the engineering department, with highly qualified professionals involved throughout the process.

Commissioning engineering is carried out by the project teams, supported by the engineering department, with highly qualified professionals involved throughout the process.

Our teams have a library of procedures and protocols, produced over more than 25 years in the execution of more than 100 projects, and a database accumulated on HMSWeb©, with more than ten million pieces of information generated by the projects carried out by the group.

Our teams have a library of procedures and protocols, produced over more than 25 years in the execution of more than 100 projects, and a database accumulated on HMSWeb©, with more than ten million pieces of information generated by the projects carried out by the group.

HMSWeb© is a complete commissioning management tool that can be used for independent activities according to the customer’s needs, integrating with the organizational solution adopted and adding value to the project.

HMSWeb© is a complete commissioning management tool that can be used for independent activities according to the customer’s needs, integrating with the organizational solution adopted and adding value to the project.

Complete management of commissioning at all stages:

Complete management of commissioning at all stages:

- General Commissioning Plan

- Critical analysis of project documentation, procurement and vendors and issuance of Technical Queries

- Risk Analysis

- Engineering and planning documentation (responsibility matrix, subsystem breakdown, precedence network, operating procedures for inspection, calibration, testing, preservation, etc.), activity protocols (ITR), schedule, personnel and material histograms, Commissioning lists and plans)

- Punch list and system transfer procedures and vendor technical assistance, operator training plan.

- Implementation of a management, control and certification system for Mechanical Completion and Commissioning

- Operation Manuals & Maintenance (O&M)

- “As-built" documentation

- Management and coordination of the execution and certification of factory tests, mechanical completion, pre-commissioning, commissioning, start-up and assisted operation

- Risk Management

- Preparing Workpackages

- Programming and Control

- Administration and operation of the management tool (HMSWeb© or another implemented in the enterprise)

- Integration and coordination of interfaces with design engineering, procurement, construction & assembly and the O&M team

- Coordination of technical assistance from suppliers, classification societies and regulatory authorities

- Hook-up management and project closure

- Pending issues coordination

- System delivery coordination

Forship has qualified and continuously trained staff, the most modern equipment, instruments and tools needed to carry out field activities. It also has complete corporate supply and logistics support to guarantee the mobilization of its teams and materials, according to the characteristics of the project.

- Inspections

- Preservation

- Electrical and Telecom Testing

- Mechanical and Piping Testing

- Instrumentation Testing

- Equipment Functional Testing

- System Performance Testing

- Reliability Testing

- Calibrations of instruments, valves and other components

- MTE NR-10 and NR-13 certification

- Start-up and pre-operation support

- Operation & Initial Maintenance

- Clearance and control of pending issues

- ‘As-built’ survey

- Commercial operation assistance

- Operator training

- Transfer of the system to commercial operation

- Project closure

- General Commissioning Plan

- Critical analysis of project documentation, procurement and vendors and issuance of Technical Queries

- Risk Analysis

- Engineering and planning documentation (responsibility matrix, subsystem breakdown, precedence network, operating procedures for inspection, calibration, testing, preservation, etc.), activity protocols (ITR), schedule, personnel and material histograms, Commissioning lists and plans)

- Punch list and system transfer procedures and vendor technical assistance, operator training plan.

- Implementation of a management, control and certification system for Mechanical Completion and Commissioning

- Operation Manuals & Maintenance (O&M)

- “As-built" documentation

- Management and coordination of the execution and certification of factory tests, mechanical completion, pre-commissioning, commissioning, start-up and assisted operation

- Risk Management

- Preparing Workpackages

- Programming and Control

- Administration and operation of the management tool (HMSWeb© or another implemented in the enterprise)

- Integration and coordination of interfaces with design engineering, procurement, construction & assembly and the O&M team

- Coordination of technical assistance from suppliers, classification societies and regulatory authorities

- Hook-up management and project closure

- Pending issues coordination

- System delivery coordination

Forship has qualified and continuously trained staff, the most modern equipment, instruments and tools needed to carry out field activities. It also has complete corporate supply and logistics support to guarantee the mobilization of its teams and materials, according to the characteristics of the project.

- Inspections

- Preservation

- Electrical and Telecom Testing

- Mechanical and Piping Testing

- Instrumentation Testing

- Equipment Functional Testing

- System Performance Testing

- Reliability Testing

- Calibrations of instruments, valves and other components

- MTE NR-10 and NR-13 certification

- Start-up and pre-operation support

- Operation & Initial Maintenance

- Clearance and control of pending issues

- ‘As-built’ survey

- Commercial operation assistance

- Operator training

- Transfer of the system to commercial operation

- Project closure